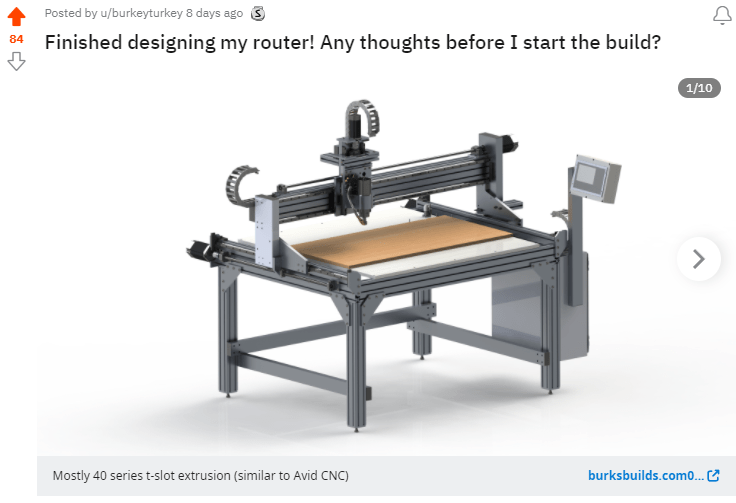

After completing the design and posting a summary on the blog I decided to solicit feedback from the folks at the r/hobbycnc subreddit. I created a post and asked for feedback, banking on the sweet renders to draw people in. The result was way better than I expected and there ended up being plenty of useful discussions in the comments and tons of great constructive feedback! The machine is going to end up measurably better in a number of ways due to the influence of the r/hobbycnc community.

Design Feedback

Of course there were a few comments that were either off topic, showed evidence that the commenter hadn’t read anything, or included obvious technical misunderstandings, but most of the top-level comments and deep threads were extremely relevant and accurate. Overall, this was way above average for a typical comment section on the open internet!

I categorized and tallied up the general feedback after things died down so I could get a list of actions to take and things to investigate:

- Table design is inadequate

- Make the table heavier, stiffer, or both

- Most technical comment thread

- Specific feedback that someone with an Avid CNC wishes the base was heavier

- Definitely bolt it to the floor

- Swap the Z axis rail and bearings (wagons)

- Provides better load paths when the Z axis is raised

- Protect the ball screws and rails (with bellows)

- Don’t rely on bearing wipers

- Optical limit switches are susceptible to false activations due to chips

- Prox sensors can work in a transverse direction if the distance is extremely consistent

- Thread with a lot of limit switch content

There were a ton of additional smaller design suggestions, component recommendations, weight saving opportunities, and build tips that I will be implementing, but only these few major architectural points are worth discussing in greater detail.

Table Design Changes

Whenever someone posts a picture of their design to the hobbycnc subreddit there is inevitably one group of people telling them that it isn’t nearly stiff enough because it isn’t made out of granite, and another group of people asking why some belt-driven off the shelf option isn’t capable of doing everything you want. I think that this large variance in feedback is due to the subreddit being the home for both small steel-cutting CNC mills and large wood-cutting CNC routers. This design is somewhere in the middle as a medium-sized aluminum cutting CNC router.

Leg Stiffness and Damping

The question I asked to everyone who mentioned that the machine wasn’t stiff or heavy enough was “how do you know when the machine is stiff or heavy enough?“.

I tried to answer this question earlier in the design process by comparing the table’s natural frequency to the cycle time of small feature milling. The only good response I got through reddit was from a user who said I should focus on damping more than natural frequency, which led me down a huge rabbit hole of stiffness and damping calculations along with the impact of mass and material choice on machine behavior.

- When the input energy is at a very low frequency (or mostly irregular) then stiffness is the dominating factor. The table legs need to not bend so far that stuff ends up in the wrong spot, but they generally only get energy from one ‘pump’ of the system.

- When the input energy is near the natural frequency of the system then damping is the dominant factor. Strain energy enters the legs with every ‘pump’ of the system, but the only ways for energy to leave the system are through destructive interference with the carriage or damping in the table.

- When the input energy is well above the natural frequency of the system then the mass of the system is the dominant factor. Each ‘pump’ of the system can’t even accelerate the mass enough to matter.

Because the mass controlled region always results in a lower displacement (for the same input force) than the other regions I am not worried about artificially increasing the mass of the table to add performance in that situation. The damping controlled region is the only region with outrageously high deflections, which appear to be inversely proportional to the input frequency (\(\omega\)) and the actual damping (\(c\)).

\( X / F = 1 / \omega c \)But what is the actual damping of the table-leg structure?

One way to approach the problem is to look at the damping ratio (\(\zeta\)) of the entire system. This parameter is defined as the ratio of the actual damping (\(c\)) to the ‘critical camping’ (\(c_c\)) of the structure, which can actually be calculated by (\(c_c = 2 m \omega_n\)).

It turns out that many materials have a ‘loss factor’ coefficient that applies fairly globally during elastic deformation (\(\eta\)) and is proportional to the damping ratio (\(\zeta = \eta / 2\)). This coefficient represents the fraction of strain energy in a spring (or bending table leg) that is lost to heat during each bending cycle. Combining all of these equations together with the definition of natural frequency (\(\omega_n = \sqrt{k / m}\)) simplifies to an equation with no references to the system mass at all:

\( X / F = 1 / 2 k \zeta \)This equation can also easily be turned into a proportionality relating to material constants, where k is proportional to the young’s modulus (elasticity) and \( \zeta \) is proportional to the elastic loss factor. This means that a material with a high product of elastic modulus and elastic loss factor would be ideally suited for minimizing the amplitude of an oscillating system.

I was unable to find an ashby chart relating modulus to loss factor (like I used to design the hard stops), but there are a few resources with tables of loss factor data. For metals, loss factor is about as low as it gets (<0.1%), with steel being about an order of magnitude better than aluminum. Because steel is also stiffer than aluminum, it ends up being a much better choice than aluminum for minimizing resonance by maximizing damping.

Materials like concrete and stone end up with an even higher modulus and loss factor product than steel! For this reason, and not necessarily their mass, they would end up being excellent choices for any structure that wants to minimize vibrations.

Wood products (and especially plywood) surprisingly have a comparable if not slightly better modulus and loss factor product than steel. While you would need much more wood than steel to get an equivalent stiffness in a structure, the wooden one might outperform the metal one! However, I would imagine the fatigue performance of steel vastly exceeds that of wood, which is probably a more important trait in cyclical loading cases anyway.

But what does the amplitude of natural frequency oscillation even mean for machine performance?

The biggest impact I can think of is that the oscillating table motion turns into oscillating acceleration on the gantry and carriage, the forces for which must come through the ball screws as if they were supplied by the motor! So as a rough goal it would be nice to keep the acceleration of the oscillations at natural frequency about an order of magnitude below the axis capability (1g) to prevent the table oscillation from overwhelming the motion control.

The instantaneous acceleration of an oscillating motion (\(a\)) is equivalent to twice the amplitude multiplied by the frequency of the oscillation, squared (\(2 X \omega^2\)). Because the amplitude of the oscillating motion (X), is given by a previous equation the maximum instantaneous acceleration of the table at its natural frequency is given as (\(a = F / 2 \pi \zeta m\)). Shockingly, in this situation the stiffness does not matter at all, and only the mass is important!

This makes intuitive sense if you think about it, because at resonance the gantry/carriage pushes on the table as much as the table pushes on the gantry/carriage (every action has an equal and opposite reaction!). And the magnitude of the input ‘pump’ force needs to match the force required to make up for one cycle’s worth of lost energy (from \(\zeta\)). For this reason, it is obvious now why steel and granite are great choices for machine tables (high mass, stiffness, and loss factor).

But how does this impact machine requirements?

The machine is designed to withstand 20g’s of acceleration in any axis (with a FOS 2) so the uncontrolled natural frequency oscillation should not exceed that acceleration. But the machine is only designed to control with 1g of acceleration in any axis (FOS 2), so it would be nice to limit the ‘typical’ acceleration due to natural frequency to below 0.1g (about an order of magnitude lower). I would argue that the ‘typical’ energy expected to enter the system would come from something like 10 holes/slots in a row, each spiral cut 10 layers deep at the natural frequency (100 cycles total).

But what does this mean for the current design?

With aluminum legs and a ‘lightweight’ 80kg aluminum table + 70kg base, oscillations at the 15-20 Hz natural frequency would result in 20-40 g’s of acceleration. If you assume only 100 ‘pumps’ ever make it into the system (compared to the 10,000 at resonance) the total energy, and therefore acceleration, is proportionally lower (0.2 – 0.4 g’s). This needs to improve by at least a factor of two.

Adding a 10-gauge (50kg) steel plate to the bottom of the table changes the max acceleration to 15-30 g’s and the ‘typical’ acceleration to 0.15 – 0.3 g’s. This lowers the natural frequency to 14-17 Hz, which still meets the 10Hz requirement.

Replacing the 3/4″ aluminum plate making up the plenum board of the main table with steel adds an extra 150kg. When combined with the lower plate previously added this reduces the max acceleration to 10-18 g’s, ‘typical’ acceleration to 0.1 – 0.2 g’s, and natural frequency to 11-13 Hz. This solution seems like the sweet spot, although I may put off adding the 3/4″ steel table until I’ve confirmed the machine’s ability to actually cut it!

Steel is without a doubt the best material choice for the legs and gussets. Steel legs and gussets would likely result in a stiffer machine with lower max amplitude. The raw material cost is fairly comparable to the aluminum extrusion and bolted plate leg design, but the dealbreaker is that I am not comfortable with or set up for steel manufacturing. The plates would be best as laser/plasma cut parts and I do not know how to weld. Fortunately, the aluminum legs and plates that I have appear to be sufficient, although just barely.

Table Stiffness

More than one commenter mentioned that the table itself could be much stiffer, to prevent oscillations of the work piece up and down. In my previous post on table stiffness, I basically only considered 2 vs 3 cross pieces without doing any math, while using the Avid CNC design to justify my choice of two cross pieces.

After doing a simple beam calculation to see what would happen if one of the 4080 cross pieces held the entirety of the 350N Z axis load I found that the deflection of the table downward (0.98mm) was three times larger than the deflection of the tool (0.034mm)!

One solution is to increase the height of the cross pieces from 4080 to 40120 t slot extrusion. This reduces the deflection down to 0.054mm but is much harder to package around the diagonal tension cables. Another option is to add 40120 ‘blocking’ to connect the two inner beams to the outer beams. This packages much better and actually reduces the deflection down to 0.023mm! This revelation is in line with the advice given by a commenter to consider adding cross braces in the other direction to increase stiffness.

One of my plans for adding more mass to the table involved bolting a 10-gauge steel plate to the bottom surface of the base. With the additional mounting points provided by the blocking and considering that there is a top plate surface as well, the design is approaching something like a ‘torsion box’ which is a common way to make a stiff base. I can also add removable blocking to the center cavity so the machine can have extra stiffness before the vacuum table is installed.

Z Axis Changes

The two most common pieces of feedback I got about the Z axis were that the rails/bearings should be swapped and the rails/ballscrew should be protected. I decided to redesign the Z axis with swapped rails/bearings then consider how I would attach bellows to each design before deciding which design to move forward with.

One of the biggest design challenges was packaging the Z axis bearings around the heavily constrained X axis bearings. The vertical spacing of the X axis bearings is fixed at 120mm because of the T slot extrusion pitch, but that doesn’t quite leave enough room in between those bearings for a Z axis bearing to fit cleanly on the opposite side of the plate.

I ended up recessing the area on the ‘front’ side of the X axis carriage plate to hide the X axis screw heads from the underside of the Z axis bearings. This recess was doubly important for mounting the Z axis rail bellows, which requires a significant amount of clearance around the bearing. This bellows clearance requirement made packaging on the old design extremely difficult (because the spindle mount was directly below the bearing) but not as burdensome on the new design.

The biggest drawback of the new design is the heavily reduced clearance around the spindle. Because the rails are mounted on the spindle side, they must reach down all the way to the nose of the spindle in order to support the plate when the spindle is raised. The only way to mitigate this problem is to raise the Z axis bearings up higher on their mount, which defeats the purpose of swapping their location with the rails in the first place!

Of course, I can always adjust the spindle’s position within its clamp to get extra clearance or extra support for a specific cut, but that is not an ideal solution. Interestingly, at about 2/3 of the stroke downward the two designs have approximately the same effective bearing arrangement as each other. This zone is also where most of the work is probably going to be done, so the stiffness advantages of the new design may not actually pay very large dividends. It is only when working near the top of the travel limit that the new design really shines.

Next, I wanted to see how the Avid CNC designed their Z axis. Which side are the bearings on, and how do they keep chips out? Well, it appears that the Avid CNC has the rails on the gantry side and bearings on the spindle side (similar to my original design), but they don’t use bellows to keep the chips out. Instead, they use thin, rigid dust covers that aren’t quite coplanar, along with a slit in the spindle carriage to navigate out of the extremely narrow opening between side covers and front cover. This is very tricky to machine but has obvious advantages in use (completely sealed Z axis!)

I decided to try modifying the original design that I had trouble fitting bellows on to work more like an Avid CNC Z Axis. I extended the 20-2010 extrusion on the side to become 20-2040 and adjusted it to only allow the smallest gap along the side of the spindle plate. The two extrusions are capped at the bottom by a 2D piece of plastic (probably laser cut acrylic) that follows the contour of the back of the spindle plate to within a millimeter.

While this setup works great when the spindle is extended (last 3″ of travel), it leaves the entire bottom of the Z Axis exposed when the spindle is retracted! Luckily, there is an easy fix if you don’t mind reconfiguring the machine. By adding a removable plastic part below the spindle plate the sealing surface can be extended downward. This lets the Z axis operate at higher positions while maintaining sealing around the bearing and screw cavity, at the expense of decreased clearance around the spindle nose. I definitely prefer this kind of reconfiguration to raising and lowering the entire spindle within its clamp and potentially invalidating the tramming.

Multiple lengths of spindle plate extenders are possible. A 50mm extender looks like a great compromise between range of motion/height and spindle access. Unless I was working on something extra-large, I think it would be reasonable to leave the software limits in the machine at 5″ of travel and keep the 50mm extender installed. With the 100mm extender I can use the full 7″ of Z axis clearance and travel. If the extender ever crashes into something, it will simply break off at the tabs and I can easily make a new one out of plastic.

Choosing between the two options is tough. Neither is strictly better than the other. The old design is simpler to manufacture and has way better spindle clearance. The new design has fewer parts and much better stiffness when machining tall objects. Both designs are sealed adequately and are comparably stiff when cutting low objects. The weaknesses of each design really only come out in corner cases (tall objects or profiles with highly varying height).

The downsides of the new design would be hard to overcome without completely redesigning the spindle (geometries that just can’t be cut), while the downsides of the old design can be overcome by turning down cut intensity (to reduce the impact of poor stiffness when cutting tall objects). Because I am only making the one machine, I need to optimize around minimizing downsides instead of maximizing upsides, therefore I will maintain the configuration with bearings on the spindle plate while adding sealing features.

Limit Switches

In a previous post I dismissed inductive proximity sensors because they aren’t great at detecting lateral motion. However, multiple commenters shared positive experiences they have had with the repeatability of prox sensors, along with negative experiences with photo-interrupt switches (mostly about false triggers from stray chips).

The problem of stray chips causing false limits is a huge issue and I’m really glad someone brought it up in the design review! I definitely can’t use these photo-interrupt sensors as limit switches if that is the case. Maybe with enough physical shielding they could work, but a major requirement of this design is robustness, so I am hesitant to count on shielding alone.

I don’t want to pivot towards using prox sensors for homing without verifying their accuracy and repeatability. My goal is for the desired machine accuracy (0.005″) to be an order of magnitude higher than the repeatability of homing within a single part. This means I need 0.013mm of lateral repeatability, which the optical sensor I had already picked out barely achieves (0.01mm).

To figure out the repeatability of an inductive prox sensor you need to look at the datasheet. A typical prox sensor has two important curves in its datasheet that looks something like this:

The first chart describes what combinations of lateral and axial distances from the center will result in the sensor tripping. On this representative “4mm” sensor, a flag with no axial spacing would be detected 3mm before it crosses the center of the sensor, while a flag with 3mm of axial spacing would not trip until the edge crossed the center of the sensor. This means that error in axial position of the flag or sensor results in approximately a 1:1 amount of error in the lateral trip point! This can be very tricky when trying to fine-adjust the position of a sensor if the axial position cannot be reliably constrained.

The second graph shows how the material and size of the flag impacts the sensing range. While the physical properties of the flag will be extremely constant and therefore not a source of error, it is important to note that material choice doesn’t just impact total sensing range but also the slope of the first graph – so an aluminum flag would result in twice as much lateral error per axial error than an iron flag! For a balance of corrosion resistance and good sensing range I would probably use a stainless steel flag.

The final factor that determines scaling range is temperature. This is probably the most important factor for me because I plan on running the machine in an unfinished garage where ambient temperature is definitely not constant! The seasonal extremes in the garage range from just above freezing to well into the 80’s (red lines), but I am mostly just concerned with day/night temperature swings (green lines) which could impact repeatability on a single part setup if I needed to re-home.

I should be able to expect about 1% variation of sensing range in my typical day/night cycle if using a standard prox sensor. On a 4mm prox this results in 0.04mm of axial error. With a stainless steel flag this becomes more than 0.05mm of transverse error (0.002″), which is 5 times larger than I can expect from the photo interrupt sensor!

There is an option to get the best of both worlds. The controller that I am using supports using a different input for the homing switches than for the limit switches. Therefore, I can use the robust inductive proximity sensors for axis limit monitoring but leverage the highly repeatable photo-interrupt sensors for homing. While this adds three more cables and sensors to the mix, it lets me use super cheap knock-off inductive proxes instead of nice brand-name proxes because I no longer care about getting extreme repeatability from the prox during homing.

The prox sensors also package way better than the photo interrupt sensors in some of the tight areas of the design. I was able to move all of the sensors off of the moving Z axis and back onto the X axis carriage, which is very convenient.

Using the T-Slots as adjustable tracks for limit switch flags has a few interesting benefits. For example, if a vise was permanently mounted on the far side (X Axis) of the table, then simply moving the one bolt on the gantry could lock out the vise area to prevent accidental crashes when using the other side of the table for sheet work. Overall, the hybrid approach seems like the best of both worlds with very few drawbacks.

Process Feedback

Beyond asking for feedback on the machine design I also asked for feedback on how to best document the build process and design. My plan already included putting CAD (Solidworks + Step + Dxf) in a repository along with part and assembly drawings (Solidworks + PDF). Rolling up the entire BOM into a spreadsheet with costs is also a fairly standard thing to do, and something I have been keeping track of already.

The most important thing I hadn’t thought about at all until it was brought up in the review was tracking the build time. For someone considering building a copy of this machine vs an Avid CNC vs PrintNC, the build time might be an even more important factor than the cost! With this in mind I’ll be sure to track my actual build time closely, probably at a subassembly level of granularity.

There was a lot of interest in something like a design/tune journal. While pictures and videos are fun to look at, people who are building and troubleshooting a copy of the machine definitely prefer printable/scrollable content. This matches my own experiences, but it was good to get that feedback directly! Certainly, I’ve been leaning on the AvidCNC web documentation a lot more than their youtube videos, but it is nice for their users that they have both options.

I have an unused burksbuilds Instagram and youtube account that I will probably start putting more content in once the build starts. They definitely serve a different purpose than the build journal (blog posts) or documentation (github) but are worthwhile efforts for getting people introduced to the project and opening a channel for direct feedback.

I’m in the “why not make it out of granite?” camp myself. I didn’t used to be that way, but I had a very interesting experience designing aerospace tooling that I think is relevant to the stiffness and vibration discussion.

Since time immemorial, the company I work for has designed and built literally monumental assembly jigs. We make small aircraft, the largest of which is less than 100ft long. But our tooling is just ungodly stout.

Historically we used 12in X 12in X 0.75in thick steel tubing for our jig frames. For critical interfaces, we’d weld two of those sections side by side, just to be sure we were stout enough. These jig frames were welded up in their final position, with the intent to never move them. At the end of production, the idea was to cut them into pieces and scrap them.

We got some new managers shortly after I started working there, and they realized that this made things hard to outsource to Mexico, because moving the work down there required rebuilding all the jigs in-situ in the new factory.

That, and they just cost a ton of money to fabricate, period. They started pushing our tool designers to make new jigs lighter and more modular. It’s a goal that I supported then and still support today, but you have to be really smart about how you do it.

We had a new program they wanted to try this on, so we had a whole string of jigs where we tried to whittle things down to the minimum structural sizes we thought were necessary, while still remaining stiff enough to meet our production tolerances.

There was a lot of cultural resistance to the idea. At the time, most of our designers were ex-tool fabricators, and didn’t have engineering degrees. Being old crusty shop guys, they didn’t mince words when sharing what they thought of the idea. I remember the phrase “this is bullshit” being tossed around a lot.

And naturally, management didn’t care about their opinions about things needing to be stiffer, even when they raised valid concerns. I can remember several times they’d roll through the office, look at designs we were working on, point to the biggest tube on the screen and ask, “why can’t that be smaller?”

I was a young, newly degreed, and ambitious engineer at the time, and instead of just indiscriminately making things lighter and thinner, I suggested we put pencil to paper and see how much material we really did need. So I started asking questions similar to the ones you’re raising here: How do you know it’s stout enough? What is the criteria? How can we predict it?

I did a bunch of finite element models to try and estimate stiffness, and I put a lot of work into trying to make sure things were going to be stiff enough. I made recommendations about where to add gussets, ran a bunch of A-B scenarios to see which was designs would be stiffer, and in general tried to make things a little more scientific than “change that tube because I said so.”

One of the largest jigs for this program was the for the wing. It was about 40ft long. It had one big simply supported truss spanning that length. I spent a lot of time making sure we’d sized that truss to be adequately stiff in the vertical direction, and I was pretty confident we were going to be successful.

A few weeks after they started fabricating that jig, I got a phone call from one of the guys building it. “You gotta come see this,” he said. I drive over to where they were working and walk over to the tool. All of the managers were milling around, and the guy building it was in a scissor lift 20ft in the air.

“Check this out!” He takes a rubber mallet and gives the side of that truss a nice whack near the center, and that thing must flexed half an inch both directions, and it vibrated like a tuning fork for a good three minutes.

The managers were horrified, “we analyzed it, how is this possible?” Well, I guess I never considered a guy would whack the side of that truss with a rubber mallet. Everybody was worried about the loads hanging from the truss, not the random side loads we might encounter. We got tunnel visioned.

To solve the problem, we welded up another truss identical to the one we already had and spliced the two together. Which ended up costing way more than if we had just designed it the traditional way, super stout. That, and I must have sunk a good four weeks of analysis time into it, all for naught. And the shop wanted to throttle me because they had to work overtime to make another truss weldment. Nobody won. Everybody lost.

A few morals to that story:

1. There comes a point at which additional analysis actually subtracts value because it delays things from progressing and could even cause you to hyperfocus on things that aren’t really be that important.

2. When steel is cheap and stiffness or increased mass is the goal, sometimes making things mindlessly stout isn’t really that bad of a solution from a cost perspective, or even a design efficiency perspective. Mass is mass, after all.

3. You’re going to miss something important. Even committees of people paid to catch mistakes miss things. Toss something out there, and band-aid it if you need to. It’s rarely so flawed as to require a complete rebuild or redesign.

And a few comments related to the design:

1. Not sure how comfortable you are with drilling holes into your concrete floor, but it’s not too difficult to bolt your machine to it. I don’t have any data to prove it, but I would think this would help absorb a lot of that vibration you’re concerned with. Google red head floor anchors for a good example. We use those at work to keep jigs that weigh thousands of pounds from tipping over.

2. I’ve used SendCutSend.com with great success for my hobby projects. Before you buy a piece of bar stock to make your gusset plates from, upload your DXF files to their website and get a quote. You might find them very competitive. Create an account, start an order, upload a bunch of parts, and then wait a month. They might send you a 10% off coupon. That was my experience, at least. Their tolerances are pretty tight, and it could save you a bunch of time and effort making those parts from scratch. Your time is at least as valuable as mine, and I sure as heck don’t have time to be cutting bar stock at a band saw and putting in bolt holes with my drill press. Unless you enjoy that sort of thing. I got kids now, ain’t got time for that.

3. Something I learned the hard way with my robot mower was that the best learning and feedback comes after you’ve built it. A good amount of analysis up front is important. But it’s a means to an end, not an end in and of itself. Be at peace with the fact that it’s not going to be perfect, even though that’s way easier said than done. I guarantee you’re going to be blindsided by some problem out of left field that you didn’t even think of once you get things up and running. But the only way to find that issue is to build your machine, as imperfect as you think it may be. And honestly, better to throw it out early while you know it’s not perfect, than to spend a lot of time getting it to where you think it’s perfect, only to become frustrated when you discover the inevitable flaws.

4. I admire your willingness to solicit feedback from strangers on the internet. I wish I had done that more with my robot mower! I probably would have discovered the vibration issues with my mower deck a lot sooner.

5. Would it be possible to find a welder in your area to weld up a steel table for you? You obviously have the chops to draw it up. If you provide material and plans, there’s a lot of folks that would be willing to come weld it up in your shop for an hourly rate that will surely be competitive. If you head this route, you might not need to lag the structure to the floor. Food for thought. Or maybe you can just find a welding table off Craigslist to use for your base? Those things are plenty stout. A pain to move, though.

I’m excited to see this thing up and running!

Thanks for all the great feedback, and I really appreciate you sharing the story about your large weldment! I definitely agree that the best way to test a design is to build it, but somehow when it’s your own money on the line instead of the company’s money getting it right the first time *feels* extra important! It was a big step in your project to send your mower frame out to get fab’d – how did the stress of that commitment compare to the stress of releasing the monument from your story?

The balance I’m trying to strike (and maybe I’ve swung a bit too far to overanalysis!) is making sure I have major trades hammered down (bearing arrangement, table architecture) because a complete redo would be prohibitively expensive, while also having cheap, add-on backup plans to ‘make things work’ if they go wrong (add some extra steel angle as gussets, plastic caps as dust covers, run the machine at lower speeds).

The permanence of bolting a machine to the floor can be daunting. I’m hoping to spend some time with the machine and verify the workflow in its current location, then bolt it (and some other stuff) to the concrete all in one go with a rental impact drill.

You’ll be happy to know that I did finally put down the pencil and start making stuff in February! The next post should cover the base and stand build, which is nearly complete.

Send Cut Send was surprisingly expensive when I got a quote. $425 for all the 3/8 plates, which can be cut from a single $60 bar. The plates were fairly easy to bang out because I could cut many edges on the miter saw, but after spending 5+ hours on each of my 3/4″ milled plates, the $100-$200 quotes I got from xometry and rapiddirect for those look like a bargain! Of course, once I have the CNC I can bang out all of these parts automatically myself…but then I won’t need them anymore 😛

I’ve stumbled into this incredible blog and would like to thank both the author and commenters. I’m currently building my own CNC and this is a gold mine.

Thanks again <3